The Dell’Orto VHSB 34(QD/QS) carburetor as fitted on the Rotax Max FR 125 engine has been delivered with two different venturi inserts by Rotax. These are either the “12.5” or the “8.5” venturi inserts. All new engines should be delivered with a carb that has the 8.5 venturi insert. This article aims to clarify the difference between these venturis and what it does to performance.

There has been a bit of confusion with what the different venturi inserts do with regards to performance because some have mistakenly assumed that the different between the 8.5 and 12.5 markings refer to a 4mm difference in the choke size, and thus influence the airflow to the engine. This is likely where the theories of “12.5 for long fast tracks and 8.5 for short twisty tracks” has come from.

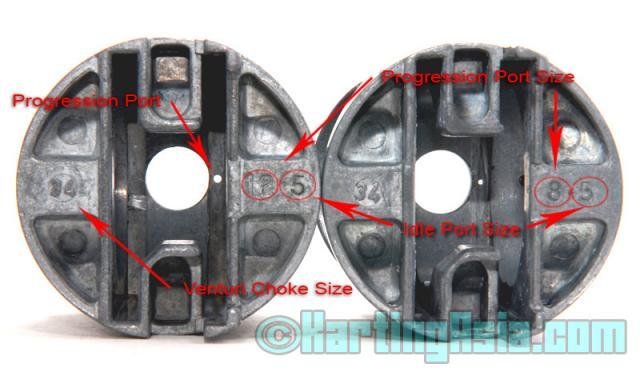

The 12.5 and 8.5 markings on the venturi insert refer to the size of two small holes – the progression port and the idle port (or progression hole and idle hole). The number before the dot (12 and 8 ) refer to the progression port. “12” means a size 120 progression hole is in the venturi while “8” means that the progression hole is size 80. This measurement uses uses the same sizing practice as the jets inside the carb – the measurement is in 100ths of a milimeter. This means that the diameter of the hole is either 1.2mm or 0.8mm. The number after the dot which for Rotax Max users is always “5” means that the idle port is size 50, or 0.5mm. Stefano Prandini from Dell’Orto S.p.A. has confirmed this.

View from the top in which you can see the different size progression ports:

The only difference between a venturi insert stamped with “12.5” or “8.5” is the size of the progression hole.

Performance Difference?

Ok now that we’ve cleared up exactly what difference is between the two venturi inserts the question is is there a difference between the two on the track? First lets try to understand what the progression port is supposed to do. In short it deals with the transition from the idle circuit (throttle closed) to the main circuit (throttle open). The progression port is located directly upstream (towards engine) of the main spray nozzle. In the picture above the direction of air and fuel-flow is from left to right. The role of the progression port comes into play as the throttle opens just a little bit.

| Here’s the explanation from the Dell’Orto Manual: |

| “As the throttle valve lifts the idle circuit air/fuel mixture decreases and the progression port begins to supply emulsified fuel. The air now comes from the main air intake. The progression port (circuit) is important to the system because of the increased amount of mixture required by the engine as the throttle leaves the closed position.The transition circuit is activated when the driver begins to open the throttle and the vacuum decreases in the idle circuit. The mixture from the idle circuit decreases and it is necessary to introduce another circuit which can supply the fuel required for the transition from idle to the main circuit. This is called the progression.At about 1/4th throttle the vacuum begins to become constant and stops drawing the mixture from the idle port. At this point the vacuum is sufficient to draw fuel from the progression port fed by the idle jet in the float chamber.”“When the valve is lifted slightly (up to about 1/4 throttle) the vacuum generated by the inducted airflow begins to be consistent, and stops drawing fuel from the idle nozzle. Under these conditions, the vacuum is sufficient; however, to draw fuel from the progression port, which is always fed by the idle jet placed in the float chamber.” |

What does all that then mean when it comes to performance? When the throttle is opened just a tad the fuel does not come through the emulsion tube yet, the progression port is there to ensure that some fuel is fed into the engine at this point – without it the mixture would be too lean with only a tiny amount of fuel coming out of the idle port. So the port only effects a small part of the throttle opening phase, which for most drivers and corners only last a fraction of a second. It likely has a small effect on initial throttle response but other than that with all else remaining the same there should be very little performance difference. Rotax likely switched from the 12.5 to the 8.5 in order to give a slightly crispier response on initial throttle application.

The venturi insert doesn’t enter into the performance equation in a considerable way in comparison to other carb changes. When I tested both back-to-back-to-back in the same carburetor I could not feel any difference when driving and my laptimes were identical. That being said others have found that there is a significant difference between the two with regards to performance so it’s best is to test it yourself and see if you find any difference. Update: The Rotax rules now mean that the venturi used also dictates what float and idle jet/idle jet insert combination you can use. This clearly makes having both venturi’s in your toolbox important if you want to change float/jet configurations.

To summarize – the different size venturi inserts are only different in the size of the progression port, and this only effects the fuel delivery from slightly open up to 1/4 throttle opening (and a very small % of total fuel flow after that).

Finally one more picture, from the bottom of the venturi insert:

I hope this article helps to clear the confusion between the 2 different venturis.